{Addressing strict requirements for hypothermic operations relies on tailored valve solution. Our organization’s cryogenic 3-way orbital piece systems are crafted to provide reliable functionality even at sub-zero temperatures, typically below -150°C. These assemblies offer remarkable circulation optimization in chilled materials such as nitrogen, oxygen, and argon, frequently used in arenas like LNG, investigative equipment, and health facilities. We emphasize durable construction, including slip-resistant locking parts and detailed production, to assure seal-tight working. Explore the upsides of improving your cryogenic system with our advanced 3-way globular assembly alternatives.

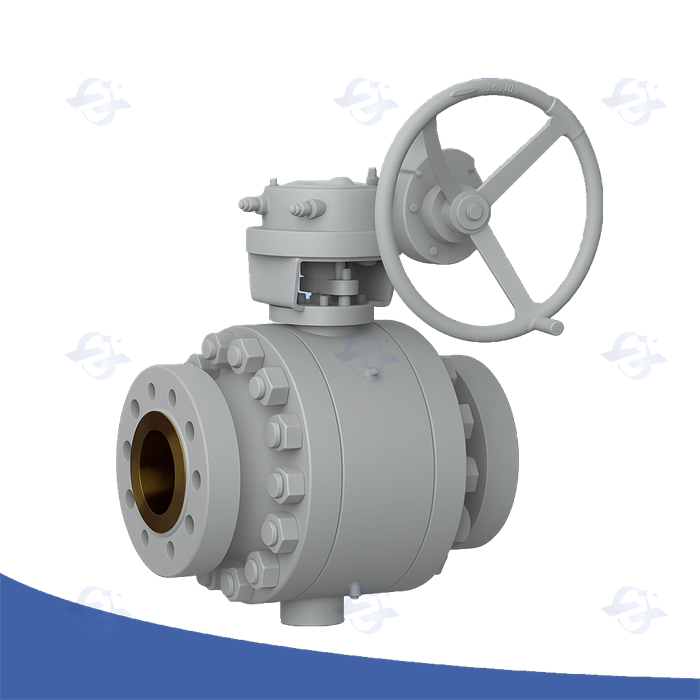

Elite Dual Closure and Drain Rotational Valve Packages

Pertaining to demanding deployments, particularly where spillage is not permitted, exemplary double block and bleed rotational valves offer unmatched safeguarding. This novel design incorporates two separate closure valve seals, plus a bleed channel, allowing for validation of the thorough shut-off and discovery of any imminent fluid escape. Generally employed in upstream activities, fabrication fabrication, and glacial locales, these systems dramatically augment operational stability and minimize the threat of natural consequence.

Three-Way Freezing Spherical Instrument Construction

This inception of tri-flow glacial rotary tap presents a singular engineering obstacle. These instruments are generally employed in key industrial operations where severe temperatures must be upheld. Key points include ingredient choice, specifically regarding embrittlement at minimal climatic states, and the must for snug locking to prevent escape of frosty gases. Complex simulation styles and rigorous production routines are crucial to warrant robust effectiveness and lastingness under such tough working circumstances.

Frozen Valve Work in Commercial Applications

Our demanding criteria of subzero services, such as subzero natural energy handling and frigid nitrogen storage, necessitate steady instrument engineering. Integral block discharge controls provide a particularly robust and effective practice to achieving zero-leak sealing while facilitating cyclical maintenance. Their design blends a primary regulator with a small escape way, allowing regulated pressure relief during termination and start-up. This inherent quality minimizes continuing content entrapment, thereby ensuring outstanding well-being and competence even under the most strict performing environments. Furthermore, the potential to track drain stream provides valuable examination statistics for process enhancement.

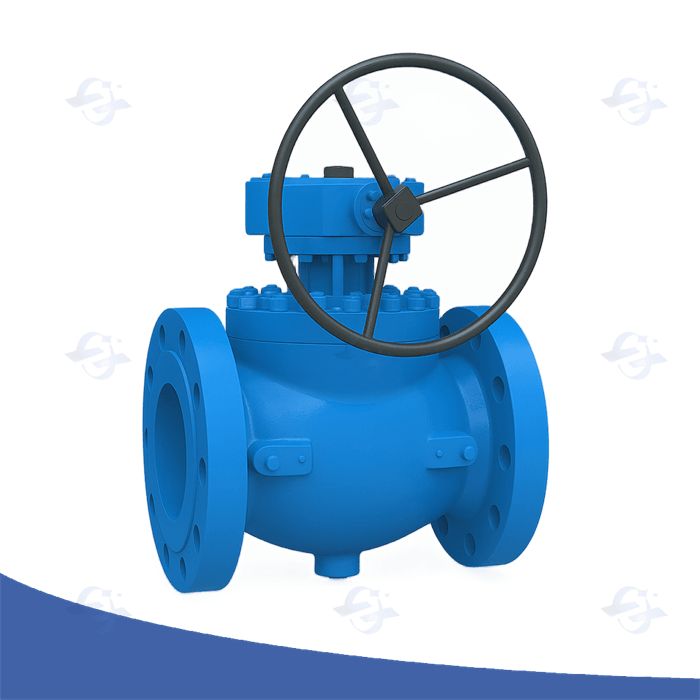

Assuring 3-Way Globular Valve Securing in Demanding High-Pressure Situations

Securing stable fastening performance with 3-way ball valves becomes particularly significant when operating within intense pressure environments. The design is obliged to account for significant pressures and potential leakage pathways. Specialized ingredients, often including superior metals like hardy steel or exotic alloys, are crucial to handle the harsh conditions. Furthermore, sophisticated fitting geometries and careful construction processes are indispensable to minimize yielding and guarantee a secure connection even under fluctuating force cycles. Regular scrutiny and preventive care programs are likewise vital for longevity and unbroken operational stability.

Frostbitten Ball Valve Leakage Prevention Strategies

Controlling "seepage" from cryogenic "globe valves" demands a multifaceted "method". Initial "formation" considerations are paramount; material "decision" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "creation" processes – including stringent weld "evaluations" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "essential" component is proper "placement"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "inspection" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "stopper”. Ultimately, a robust "structure" incorporating these elements is necessary to ensure the safe and efficient "execution" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shrinking", safety "threats", and costly "interruption”.

Double Closure and Escape Instrument Verification Plans

To maintain the integrity and safety of critical piping frameworks, rigorous dual closure and release device examination techniques are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the purge tool remains functional and correctly discharges any trapped substance. A common system is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the exfiltration rate around the closed units is meticulously appraised. The release system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of evaluation results, including any variations observed, is vital for maintaining a reliable activity.

Comprehending Comprehensive Block Emission Device Capability

To fully supervise power networks, a comprehensive comprehension of integral block escape unit functionality is completely paramount. These specific devices predominantly behave to effectively free unwanted compression from a installation during pre-determined utilized intervals. A ordinary laying consists of a fitted compartment joined to the principal pressure source, authorizing specific led emission if necessary. The essential format lessens the possibility of surpass of threshold pressure, guarding both the gear and the proximate surroundings. Regular examination and preservation are essential to safeguard top performance.

Electing the Proper 3-Way Ball Valve for Cryogenic Fluids

Deciding on a appropriate 3-three-ball tool for cryogenic processes demands careful review of several critical components. The extremely low cold states inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material preference is paramount; only materials with proven compatibility and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized refined alloys, should be examined. Furthermore, the component's sealing effectiveness is vital to prevent leaks, requiring proprietary stem sealing patterns and low-temperature substances. Finally, pressure gradings and actuation methods, taking into account potential pressure surges, must be meticulously matched to the system's specifications. Neglecting these features can lead to devastating failure and safety jeopardies.

Frostbitten Globe Valve Material Compatibility Guide

Selecting the appropriate material for cryogenic ball valves is paramount, given the demanding temperatures involved. This tome highlights common compounds and their efficiency when exposed to cryogenic fluids such as substance nitrogen, coolant helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate strength and deterioration resistance, though martensitic substances require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their malleability and resistance to specific chemicals needs in-depth evaluation. Copper alloys, while offering some positives, may exhibit diminished competence at these lowered temperatures. Consultation with producers and comprehensive scrutiny is essential to secure stability and dependability in cryogenic processes.

Elevating Twin Seal and Vent Construction Effectiveness

Accomplishing optimal efficiency in double seal and release setups hinges on a multifaceted plan. Careful evaluation of unit selection is crucial, with a focus on substance conformity and impact classification. Regular check of release passages for obstruction is necessary, often calling for the use of professional assessment apparatuses. Furthermore, process refinement—including checking of passage rates and strain gap—can dramatically amplify overall framework firmness and guarding. Finally, alignment to fabricator directives and the enforcement of a complete maintenance routine are critical for long-term sustainability and lastingness.

best cryogenic ball valves

best cryogenic ball valves