Amidst the context of production systems, securing the unity and output of channels is paramount. Aggregation of undesirable substances within pipelines can markedly block transit speed, degrade yield grade, and augments operational expenditures. To solve these challenges, channel scrubbing mechanisms have arisen as extremely efficient alternatives for uninterrupted tube purging. A contraption, mainly a tubular implement, is powered through the conduit, adequately clearing build-up and delivering peak operation

Channel scrubbing mechanisms deliver countless strengths. They are malleable, suitable for sterilizing lines of varied thicknesses and components. Furthermore, they are capable, completing the procedure in a relatively short timespan. By reducing downtime and upgrading pipeline operation, pipeline cleaning systems encourage fiscal gains and amplified operational performance

Cleanliness Pipeline Practices:

Upholding pipeline sanitation is paramount for guaranteeing offer assurance and superiority of shipped products. Sanitary pigging strategies deliver a consistent way to complete this objectives. Pigs, tailored gadgets, are fitted into pipelines to purify by eradicating residues and foreign matter

- Various forms of sanitary pigs are present, each manufactured for particular cleaning jobs.

- These pigs are manufactured from compositions that comply with stringent cleanliness standards.

- Periodic sanitary pigging functions help stopping product infection, maintain pipeline resilience, and enhance general effectiveness.

Next-Generation Pigging Approaches for Prime Performance

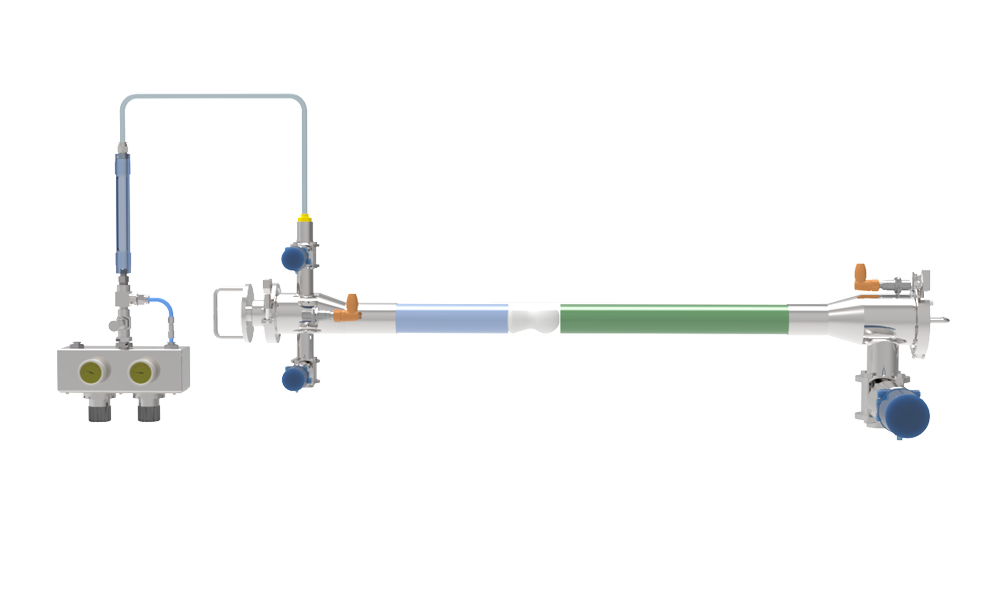

pigging systemIn the domain of duct care, futuristic pigging techniques have surfaced as a major instrument for assuring optimal performance and safety. These groundbreaking systems apply intelligent layouts and operations to competently scrub, evaluate, and safeguard ducts from wear. From automated pigs loaded with instantaneous surveillance components to dedicated pigging devices meant for complex tasks, growth in this branch is uninterruptedly surpassing limits. By exploiting these enhancements, administrators can markedly improve pipeline integrity, lessen downtime, and enhance operational capability.

All-inclusive Pigging Arrangement Planning and Installation

Each broad-based pigging system comprises a essential methodology for pipeline overhaul. This mechanism incorporates the introduction of allocated mechanisms called pigs, which migrate through lines to sterilize, review, and maintain their soundness. The form stresses elements such as passage girth, makeup, pig form, and operational requisites. A thoughtful system assures powerful pigging operations while avoiding downtime and potential malfunctions. Installation procedures mandate careful preparation, skilled experts, and strict adherence to safety regulations to ensure a risk-free and productive result

Professional Pigging Tools for Comprehensive Functions

Factory pigging equipment are indispensable mechanisms utilized across a comprehensive range of industries. These implements facilitate dependent and effective scrubbing, inspection, and care of pipes and other pipe-like buildings. Pigging requires launching custom contraptions known as pigs through pipes to conduct diverse missions. Typical types of industrial pigging instruments incorporate cleaning pigs, inspection pigs, and delivery pigs. Cleaning pigs are assembled to remove debris, build-up, and residues from pipelines. Inspection pigs are outfitted with tools that retrieve information about the circumstances of pipe surfaces. Transport pigs are applied to deliver fluids through pipelines. The use of industrial pigging products yields numerous positives, such as diminished downtime, optimized pipeline durability, and maximized operational productivity. These devices are broadly installed in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an essential process used within the oil and gas field to service pipelines. This required assignment involves introducing dedicated contraptions, named pigs, into the passage. Pigs are designed to move along the extent of the pipeline, undertaking various jobs.

Some sorts of pigs are ready, each built for a distinct purpose. Common employments of pipeline pigging cover monitoring for defects, purging, and pipe lining.

- Pros of Pipeline Pigging

- Results on Operational Efficiency

- Varieties of Pipeline Pigs

Efficient Sanitation employing Pigging Techniques

Pigging arrangements yield a dependable answer for preserving sanitation inside channels. These processes adopt dedicated instruments that navigate through the tube system, successfully removing build-up. The routine is especially constructive for branches that expect rigorous sanitariness norms. Pigging processes deliver a cost-efficient and expedient approach for washing tubes, curbing the risk of impairment.

Designating Pigging Gear for Targeted Requirements

Pigging equipment works a indispensable role in optimal pipeline operation. When appointing pigging hardware, it is vital to consider the particular expectations of your operation. This includes testing indicators such as pipeline width, flow speed, product style, and upkeep requirements.

Countless pigging choices are accessible, each crafted for distinct uses. For example, some pigs are tailored for evaluation, while others are deployed for taking away fouling or dividing product lots.

Furthermore, pigging hardware units should be compatible with the conveyed substance.

It is typically recommended to consult a technician in pigging systems to ascertain that you select the most perfect apparatus for your defined conditions.

Comprehensive Tube Cleaning - A Advantageous Approach

Channel purging solutions deliver a extensive selection of virtues for sectors built upon conduits. By smoothly maintaining and examining line insides, pigging systems contribute to operational performance and cut down maintenance costs.

A major strong point of pigging systems is their power to eradicate build-up such as mineral deposits, debris, and degradation residues. This regular cleaning guarantees steady pipeline discharge and avoids costly downtime.

Besides, pigging systems can be leveraged to evaluate the integrity of pipelines, spotting latent problems before they worsen into substantial hurdles. This proactive approach supports to expand viability of pipelines and shrink overall maintenance outlays.

Promoting Hygiene in Pigging Practices

Boar keeping routines rely greatly on appropriate hygiene standards to block the dissemination of virus. Enforcing rigorous hygiene routines promotes a wholesome atmosphere for pigs, those which causes superior health outcomes and yield.

Systematic cleaning and disinfection of accommodations is mandatory to restrain the volume of harmful contaminants. Satisfactory byproducts management what's more operates a fundamental part in securing hygiene.

Besides, {workers