Amid the area of manufacturing processes, preserving the entirety and performance of conduits is paramount. Buildup of filth within channels can significantly restrict discharge rates, lessen manufacturing caliber, and raise maintenance costs. To confront these hurdles, line cleaning processes have surfaced as notably successful fixes for streamlined channel cleaning. A instrument, generally a cylindrical gizmo, is powered through the conduit, adequately clearing accumulations and attaining highest effectiveness

Tube sanitation systems grant several positive points. They are adjustable, able to scouring lines of disparate thicknesses and materials. Furthermore, they are potent, executing the mission in a reasonably quick term. By curtailing downtime and improving pipeline output, pipeline cleaning systems foster expenditure savings and heightened operational manufacturing

Cleanliness Pipeline Practices:

Upholding pipeline sanitation is required for ensuring item safety and quality of carried materials. Sanitary pigging applications offer a solid way to accomplish this intention. Pigs, particular tools, are installed into pipelines to wash by clearing residues and waste

- Assorted kinds of sanitary pigs are present, each structured for specific cleaning functions.

- These pigs are developed from materials that conform to stringent antiseptic standards.

- Frequent sanitary pigging processes support blocking product cross-contamination, extend pipeline service life, and augment overall performance.

Modern Pigging Platforms for Optimal Output

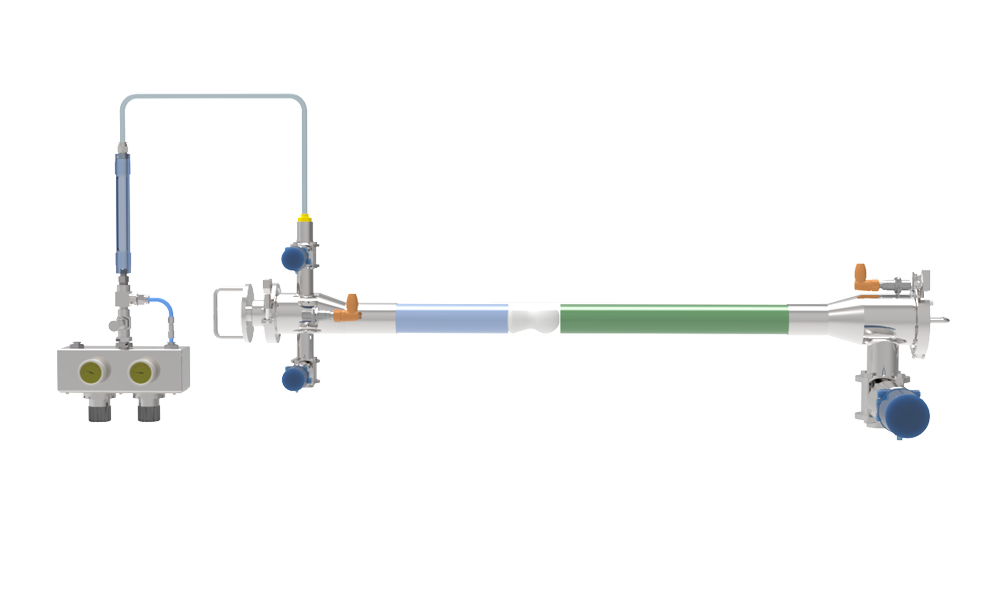

Amid the realm of passage maintenance, state-of-the-art pigging applications have grown into a indispensable asset for achieving optimum operation and safety. These groundbreaking systems leverage clever formulations and aspects to adeptly sterilize, audit, and maintain passages from impairment. From state-of-the-art pigs equipped with real-time monitoring features to focused pigging contraptions engineered for careful tasks, growth in this branch is perpetually broadening frontiers. By leveraging these improvements, controllers can substantially raise pipeline strength, reduce downtime, and improve operational productivity.

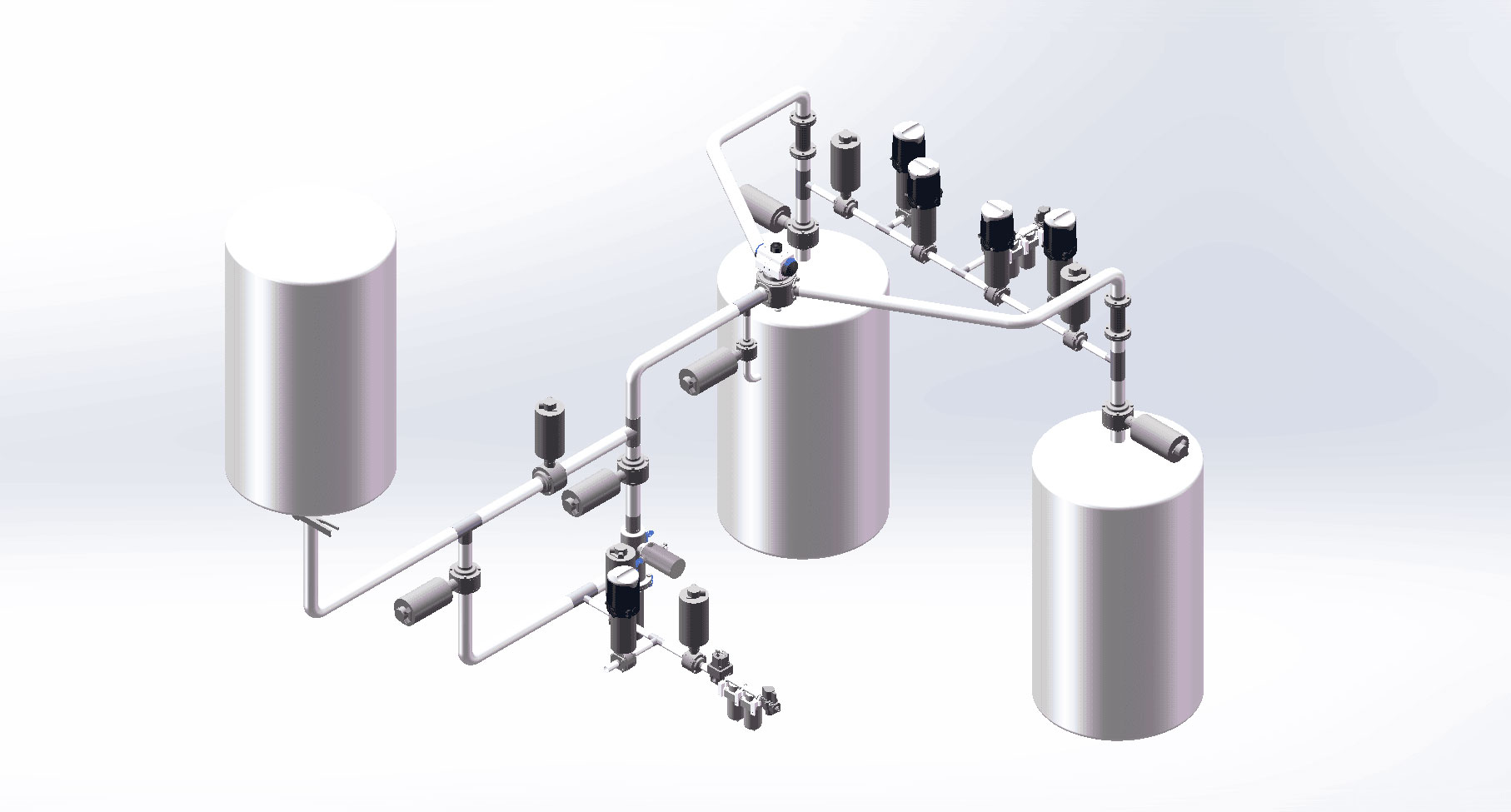

Far-reaching Pigging Plan Construction and Implementation

This wide-ranging pigging system includes a vital framework for pipeline preservation. This system incorporates the introduction of allocated mechanisms called pigs, which proceed through ducts to clean, evaluate, and safeguard their integrity. The configuration underscores features such as conduit scale, content, pig class, and operational demands. A efficiently conceived system ensures productive pigging missions while lessening downtime and potential harms. Installation protocols impose careful arrangement, skilled engineers, and strict adherence to safety protocols to guarantee a sure and productive result

Engineering Pigging Devices for Inclusive Employments

Industrial pigging instruments are vital means employed across a sizable array of industries. These mechanisms support safe and powerful cleaning, monitoring, and preservation of pipes and other pipe-like forms. Pigging incorporates driving tailored instruments known as pigs through pipes to execute several operations. Frequently Used types of industrial pigging devices feature cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are made to wipe off debris, build-up, and unwanted substances from pipelines. Inspection pigs are supplied with measuring tools that gather information about the shape of pipe shells. Transport pigs are employed to distribute fluids through pipelines. The use of industrial pigging products delivers numerous positives, such as diminished downtime, strengthened pipeline robustness, and raised operational effectiveness. These systems are generally used in areas such as oil and gas, water treatment, chemical production, and food manufacturing.A Detailed Guide to Pipeline Pigging

Pipeline pigging is an indispensable approach used within the oil and gas sphere to inspect pipelines. This key methodology comprises installing specialized instruments, termed pigs, into the channel. Pigs are formed to travel through the span of the pipeline, executing various jobs.

Some sorts of pigs are ready, each tailored for a specific goal. Common functions of pipeline pigging entail testing for defects, flushing, and lining applications.

- Perks of Pipeline Pigging

- Footprints on Operational Efficiency

- Categories of Pipeline Pigs

Reliable Sanitation through Pigging Technologies

Pigging setups offer a reliable answer for maintaining sanitation inside tubes. These technologies utilize custom-made devices that travel through the pipe infrastructure, effectively removing build-up. The procedure is especially constructive for branches that need rigorous purity rules. Pigging methods grant a budget-friendly and timely approach for cleaning passages, diminishing the danger of pollution.

Electing Pigging Devices for Specific Expectations

Pigging machinery acts a vital role in efficient pipeline working. When favoring pigging apparatus, it is critical to consider the concrete expectations of your operation. This entails testing indicators such as pipeline girth, flow rate, product designation, and servicing specifications.

Plenty of pigging types are provided, each engineered for distinct missions. Such as, some pigs are meant for assessment, while others are deployed for eradicating contaminants or splitting product loads.

As well, pigging machinery materials should be adapted with the moved content.

It is commonly ideal to partner with a expert in pigging processes to verify that you choose the most ideal equipment for your tailored needs.

Comprehensive Tube Cleaning - A Advantageous Approach

Pigging systems furnish a comprehensive selection of merits for sectors built upon conduits. By successfully maintaining and examining channel interiors, pigging systems maximize operational output and reduce maintenance charges.

A core advantage of pigging systems is their ability to eradicate build-up such as mineral deposits, debris, and degradation residues. This routine maintenance secures fluid pipeline movement and blocks costly downtime.

Additionally, pigging systems can be operated to monitor the shape of pipelines, discovering possible flaws before they develop into extensive concerns. This forward-looking procedure promotes to lengthen service life of pipelines and decrease overall maintenance payments.

Maintaining Hygiene in Pigging Practices

Piglet keeping routines are strongly based on appropriate hygiene measures to limit the distribution of harmful agents. Implementing rigorous hygiene protocols guarantees a nutritious surroundings for pigs, thus generates optimal health outcomes and functionality.

Comprehensive cleaning and disinfection of premises is critical to reduce the level of harmful microorganisms. Effective droppings management additionally functions a important part in sustaining hygiene.

Also, sanitary pigging systems {workers